Productivity and OEE management

Continuous improvement

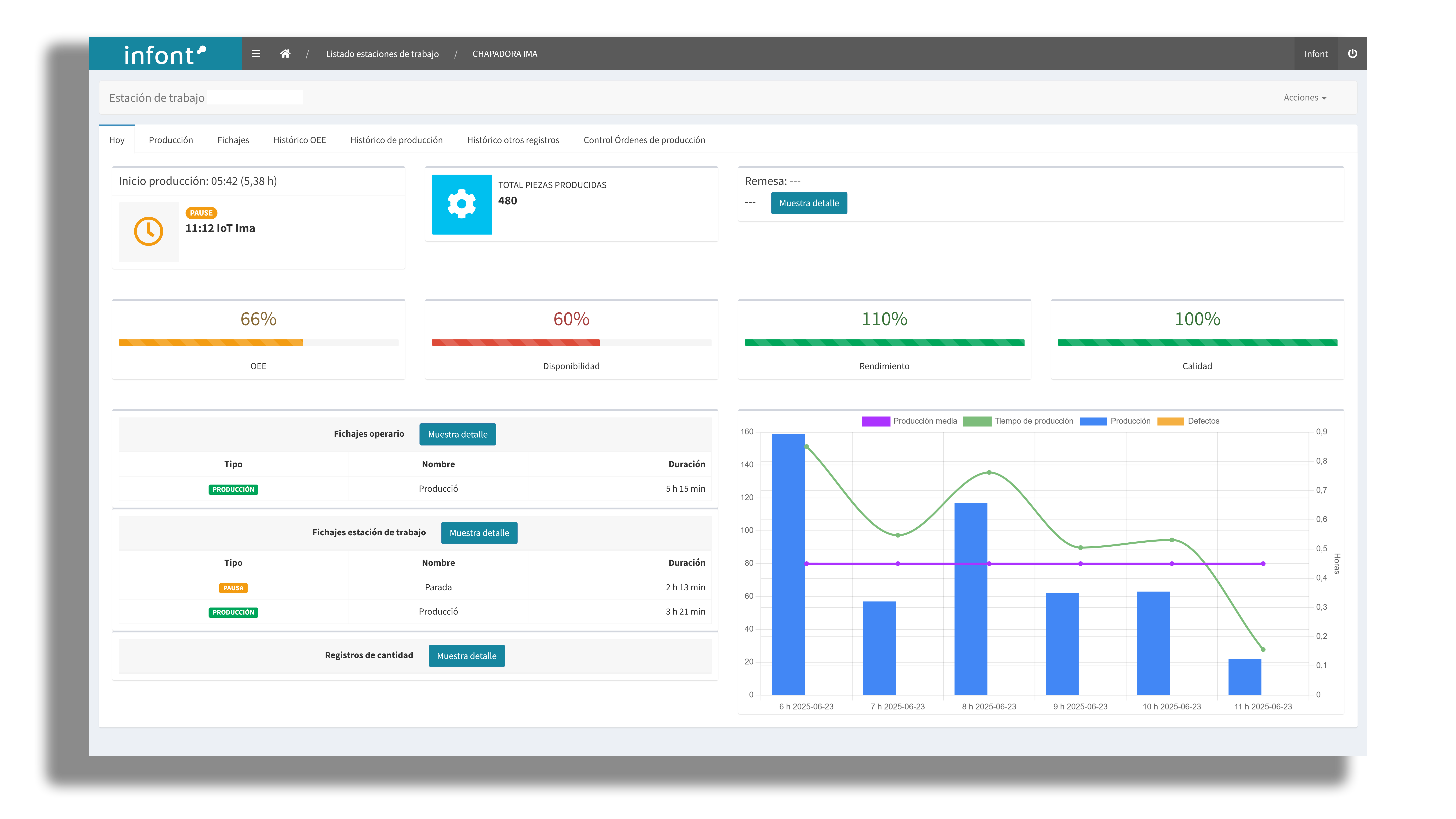

Set specific goals per workstation and assess the state of each parameter of your OEE (Overall Equipment Effectiveness) to drive continuous process improvement.

Quality

Record defective productions in detail to accurately track quality and detect improvement areas.

Performance

Monitor and analyze operator working times to get a clear view of each station's actual performance.

Parameterization

Configure time records according to your production environment's needs. The system’s flexibility allows efficient and tailored tracking.

How we work?

Specification

We analyze your plant's needs and jointly define the functional and technical requirements to ensure optimal adaptation of Infont to your production environment.

Data integration

We connect Infont with existing data sources via our REST API. We can integrate data from machine files, other Infont modules or external databases.

Implementation

We deploy the solution in your working environment, configuring stations, processes and user roles according to established requirements.

Validation

We ensure collected data is reliable, consistent and useful for analysis. We validate the system’s performance and support you during the first days of use.

All the information you need, in real time.

Visualize real-time key data from your workstation: hourly output, effective hours, breaks, and stoppages. Check number of pieces produced and monitor OEE indicators clearly and accessibly.